|

Pearl and gold setting that was originally an

engagement ring given by a WWI Doughboy. |

Barbara purchased the opal for this necklace on a

recent trip to Australia. But the gold for the pendant comes from three

rings that she has had for many years. When Barbara was nine years old, her mother's

best friend, Iona, gave her a little pearl ring. Iona had been

engaged when she was 18 years old, but her fianc� died in WWI before

they could marry. To make this necklace, the front of the pearl

ring was cut away and straightened to make the top right section of the frame.

The rest of the ring was melted along with the setting from Barbara's

original engagement ring and an opal ring that had originally been a

gift to her grandmother, purchased by her uncle at the San Francisco

World's Fair in 1915. That ring

had lost a stone on August 15, 1945, "VJ Day". The old gold was cast to make the frame for this

necklace and the remainder saved for a future project for Barbara's

grandchildren. Lots of memories in this piece. |

Jeanne's engagement ring. Incorporating gold left

from her grandmother Barbara's project on the left.

Click for details.

Legacy Gold

Walker

Metalsmiths Home

Contact Walker Metalsmiths

1 Main St. Andover, NY 14806

Phone 1-800-488-6347

[email protected] |

|

|

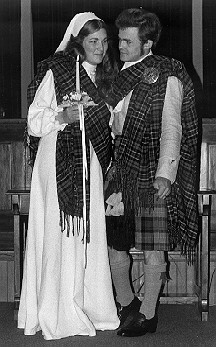

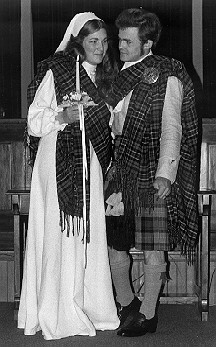

Rory and Deborah celebrated their 25th wedding anniversary with new

rings. After choosing designs, Stephen Walker prepared the lost wax

molds for casting so that the couple was able to arrive at the workshop

wearing their original rings. These were then remelted and cast while

they watched. Soon their new rings were cooled, filed

and polished so that they left wearing new rings, recycled from the original

material from their wedding.

Watch similar rings being made on YouTube

Watch similar rings being made on YouTube |

|

|

Homemade engagement ring tricked

out with a diamond and gold trim after 35 years. |

When Joe was 19 years old he made a ring by

braiding stainless steel wire and gave this to Liz as an engagement

ring. The ring broke, but the marriage was a great success. 35 years

later Joe brought some old gold rings to Walker Metalsmiths. A diamond

was added and the original homemade ring was rebuilt. |

Listen to Liz tell

her story on YouTube |

|

Before:

Original engagement ring from 1980s |

For their 25th anniversary this couple had us take the quarter carat

diamond from their original engagement ring and make it into a necklace

for their daughter. The gold was then used to cast the ring shown on the

right, which is a custom setting built to hold three cushion cut

diamonds. 2.10 carats total weight. |

New ring from Walker Metalsmiths

|

|

Doug and Juanita panned for gold on trips to South

Carolina. After Juanita passed away Doug had Walker Metalsmiths take the

stone from one of her rings and set it in a ring cast from the gold that

they found together. The natural gold tested

at 22K. The shank of the 14K ring and some additional metal was

added to make the final alloy 14K. |

|

|

|

Lost

Wax Casting

How it is done

Watch it on YouTube!

1. Old gold is tested and weighed. New gold or alloy

material is added as

needed.

|

2. The design of the ring is modeled in wax. In the

illustration the waxes are multiples made in rubber molds. The original

carving for each design is either carved in a special carving wax or

made directly in metal. The two wax rings in the front will be cast

together remelting old gold.

|

3. The wax is enclosed in a steel flask and filled

with a plaster investment material. This is heated in a kiln to melt and

burn out the wax leaving a cavity the exact same shape as the wax. |

|

4. The flask is put in a centrifugal casting machine while it is

still hot from the kiln. The gold is melted with a torch and the spun

into the investment mold. |

Spinning the cast. A blur of motion

.

|

5. The flask is allowed to cool for several

minutes and then quenched in water. It is still hot enough that the

thermal shock explodes the investment away from the castings. (The picture is actually a different

casting than the wax illustrated, but you get the idea) |

|

6. The casting gates are cut off and saved for future

projects and the pieces are filed and polished. |

|

The final product.

Discover

the design possibilities at Walker Metalsmiths |

Watch similar rings being made on YouTube

Watch similar rings being made on YouTube